Screen Printer

Our Setup:

Custom foils are combined with various chocks to allow pastes and viscous materials to be deposited by screen printing. Typically used to quickly deposit conductive paste such as silver glue onto all of the bondpads of a chip or carrier at once, screens have features down to 300 x 300 µm. Our foils allow us to spot up to 64 positions in several seconds. Foils up to A3 size can be used.

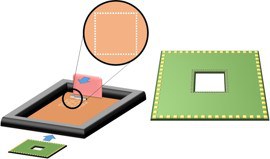

Screen Printing

A substrate material (in our case typically chips or carriers) is placed under a stiff but flexible foil that has holes cut out to match a structure on the substrate. A chock holds the substrate in close contact with the foil from below, and allows the pattern of holes to be aligned to the substrate. A line of viscous or paste-like material to be deposited on the substrate is applied next to the holes on the top side of the foil. A rubber scraper is then drawn across the foil to spread the paste over the pattern of holes. At the position of the holes, the paste is structured to have the lateral shape and dimensions of the hole, and the thickness of the foil.

Features:

| Maximum Array Size | A4 |

| Maximum Substrate Height | 10 cm |

| Print thickness | 125 µm |

| Resolution of features depends on foil manufacturer |

Contact:

Dr. Vanessa Maybeck

Tel.: +49-2461-61-3675

e-mail: v.maybeck@fz-juelich.de